通常包括以下几个步骤:

1. 材料准备:选择合适的陶瓷材料,如氧化铝、碳化硅等,并确保其质量符合要求。

2. 成形:将陶瓷材料按照设计要求进行成形,常见的成形方法包括注射成型、挤压成型、等离子喷涂等。

3. 烧结:成形后的陶瓷制品需要进行高温烧结,使其颗粒结合成坚固的整体。烧结温度和时间根据材料的种类和要求而定。

4. 精加工:烧结后的陶瓷制品需要进行精细加工,以达到更高的精度和光洁度。精加工包括研磨、抛光、激光加工等工艺。

5. 检测和质量控制:对加工后的陶瓷轴承进行各项检测,如尺寸、硬度、表面光洁度等指标的检测,确保产品符合质量标准。

6. 组装:对精加工后的陶瓷轴承进行组装,将轴承套和滚珠等零部件组装在一起,并进行润滑和密封。

7. 检验和包装:对组装好的陶瓷轴承进行的检验,确保产品质量,然后进行包装,以便运输和销售。

8. 性能测试:经过表面处理后的陶瓷轴承需要进行性能测试,以确保其满足设计要求和使用要求。常见的性能测试包括摩擦测试、耐磨性测试、承载能力测试等。

9. 包装和出厂:经过所有的加工和测试后,陶瓷轴承需要进行的包装,并安排出厂。包装通常会采用适合的材料和方式,以保护陶瓷轴承免受损。

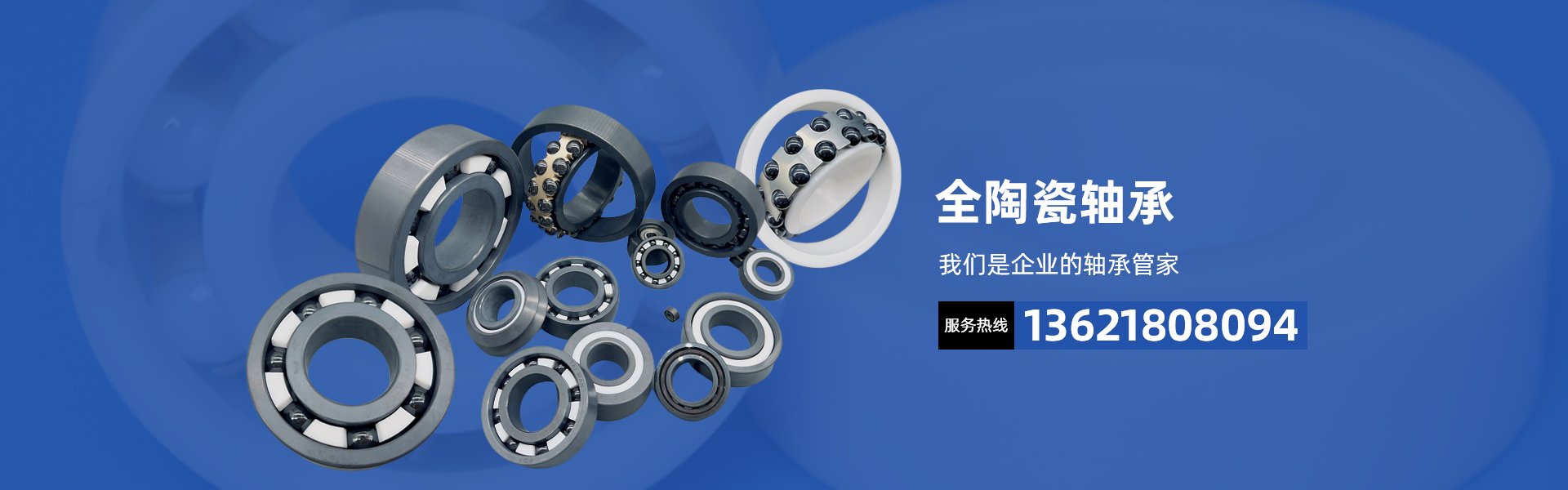

需要在耐酸、耐碱、耐高温、耐低温、抗磁电绝缘等工况中可以选择陶瓷轴承,为您的生产提高高能的效率。

The processing process of ceramic bearings usually includes the following steps:

1. Material preparation: Select suitable ceramic materials, such as aluminum oxide, silicon carbide, etc., and ensure that their quality meets the requirements.

2. Forming: Forming ceramic materials according to design requirements, common forming methods include injection molding, extrusion molding, plasma spraying, etc.

3. Sintering: The formed ceramic products require high-temperature sintering to combine their particles into a solid whole. The sintering temperature and time depend on the type and requirements of the material.

4. Fine processing: The sintered ceramic products require fine processing to achieve higher accuracy and smoothness. Precision machining includes processes such as grinding, polishing, and laser processing.

5. Testing and quality control: Conduct various tests on the processed ceramic bearings, such as size, hardness, surface finish, and other indicators, to ensure that the products meet quality standards.

6. Assembly: Assemble the ceramic bearings after precision machining, assemble the bearing sleeves, balls, and other components together, and lubricate and seal them.

7. Inspection and Packaging: Inspection of assembled ceramic bearings to ensure product quality, followed by packaging for transportation and sales.

8. Performance testing: After surface treatment, ceramic bearings need to undergo performance testing to ensure that they meet design and usage requirements. Common performance tests include friction testing, wear resistance testing, load-bearing capacity testing, etc.

9. Packaging and Delivery: After all processing and testing, ceramic bearings need to be packaged and arranged for delivery. Packaging usually uses suitable materials and methods to protect ceramic bearings from damage.

Ceramic bearings can be selected in conditions such as acid resistance, alkali resistance, high temperature resistance, low temperature resistance, and magnetoelectric insulation to improve high-energy efficiency for your production.

选择陶瓷轴承

选择上海安鼎亿泰

我们是企业的轴承管家

我们一直都在